In Grain Bin Drying

Air drying in a grain bin is a fundamental process in agricultural storage that relies on key principles to preserve and protect harvested crops. The primary objective is to reduce moisture content, preventing spoilage and maintaining grain quality.

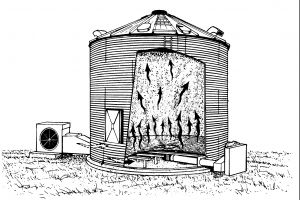

The first principle involves proper aeration, where ambient air is circulated through the grain mass. This promotes uniform drying and minimizes temperature differentials within the bin. Effective aeration systems incorporate strategically placed fans that move air through the grain, ensuring even distribution.

Humidity control is another crucial principle. As air passes through the grain bed, it absorbs moisture, facilitating the drying process. Managing humidity levels is essential to prevent reabsorption of moisture by the grain. Monitoring tools, such as hygrometers, aid in optimizing conditions for efficient drying.

Temperature regulation plays a pivotal role in air drying. While warm air enhances moisture absorption, excessive heat can lead to grain damage. Striking a balance by monitoring and controlling the temperature of the drying air is essential for preserving both the structural integrity and nutritional value of the grain.

Lastly, the grain bin design itself influences air drying efficiency. Factors such as bin size, vent placement, and insulation impact the effectiveness of the drying process. Adequate ventilation, insulation, and a well-designed aeration system collectively contribute to the successful application of air drying principles in grain bins, ensuring the long-term storage of high-quality, market-ready crops.

At T&S Sales we utilize multiple ways to achieve great grain quality from standard full natural air dry, low heat grain bin heaters, to high heat in bin drying. We can help you achieve a quality crop on your farm the economical way.

Our Work

Principles of Grain Drying

Drying is one of the oldest methods of preserving food and feedstock. It is simply the removal of moisture from a product, usually by forcing dry air through the material.

Air serves two basic functions in grain drying. First, the air supplies the necessary heat for moisture evaporation; second, the air serves as a carrier of the evaporated moisture. Both functions are essential regardless of the type drier you use. The amount of moisture that can be removed from grain depends on the moisture content of the grain, and the relative humidity and temperature of the drying air.

Air temperature determines to a large extent the total water-carrying capacity of the drying air. Hot air can hold more moisture than cold air. For example, a pound of air at 40 degrees F can hold only 40 grains of moisture (7,000 grains = 1 pound), while a pound of 80 degrees F air can hold 155 grains — almost a four-fold increase.

The temperature of the drying air also affects the dried grain quality. Grain to be fed or milled can be dried at 150 degrees F or higher, while grain for seed should not be heated above 110 degrees F or reduced germination occurs. High heat often cracks the seed coat leading to grain breakage in handling.

Relative humidity also plays an important part in the drying process. Air at 100 degrees F and 50 percent relative humidity can absorb 60 more grains of moisture per pound of air than it can at 75 percent humidity.

When grain is placed in a dryer and air is forced through the grain, a drying zone is established at the point where the air enters the facility. The drying zone moves uniformly through the grain in the direction of air flow at a rate depending on the volume, temperature and relative humidity of the air and the moisture content of the grain.

Forcing air through deep layers of grain is more difficult and requires more fan capacity and horsepower than forcing air through thin layers of grain. The pressure built up by the fan due to the resistance of air flow through grain is called static pressure and is normally measured in inches of water. The pressure increases as grain depth and air flow rate increases. Grain such as wheat or grain sorghum has less void space than corn. Less void space for air to move through requires more static pressure.

Grain management allows you to simply and cost-effectively protect your investment.

As opposed to the classical approach of reactive monitoring, OPI’s advanced grain storage management takes a proactive approach to ensuring the highest possible return on your grain assets with grain temperature monitoring and grain moisture monitoring. Rather than seeing grain storage as a cost center, we want you to be in the driver’s seat—dictating market terms and extracting the highest-possible value through the application of our market-enabling technology.